MAG 40

Category

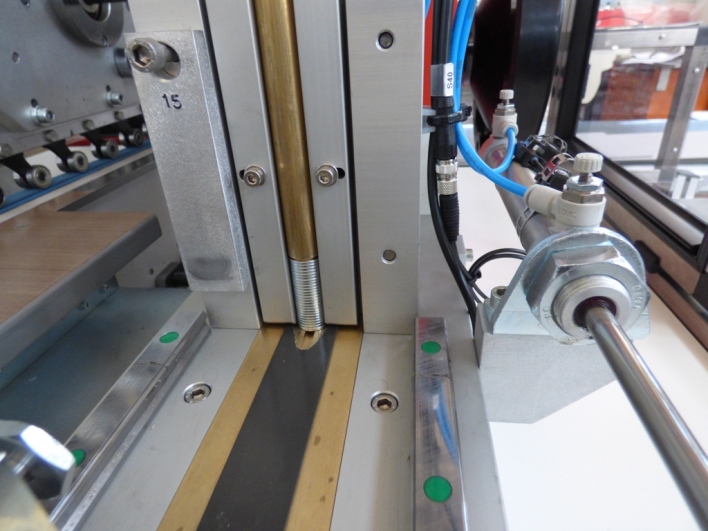

Automatic machine to apply magnets and metal plates, Machines for collapsible boxesAUTOMATIC MACHINE TO APPLY MAGNETS AND METAL PLATES

Fully automatic machine to groove board seats and to apply 2 or 4 magnets by using hot-melt glue.

Board cases and magnets fed from proper chargers by automatic cycle

Supplied with final (nested) collecting unit of the end products.

Technical features

Used materials:

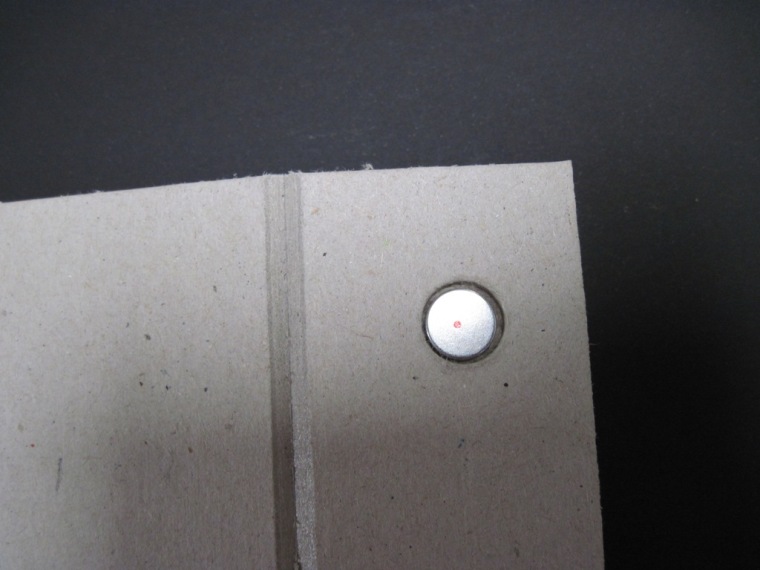

– grey board with thickness from 1,5 mm up to 4 mm

– magnets with diam. min 9,5 mm and max 15 mm/thickness 1mm, 1,5mm and 2 mm

Board size range:

min. 230 mm x 150 mm

max 800 mm x 400 mm

Magnet distance: min. 180 mm – max 750 mm

Production:

– 40 pieces/minute (with 2 magnets)

– 20 pieces/minute (with 4 magnets)

Electrical power required: 7 Kw

Pneumatic consumption: 350 NL/minute (6 bar)

Overall dimensions: L=4000mm W=3000mm H=2100mm