MAG 1

Category

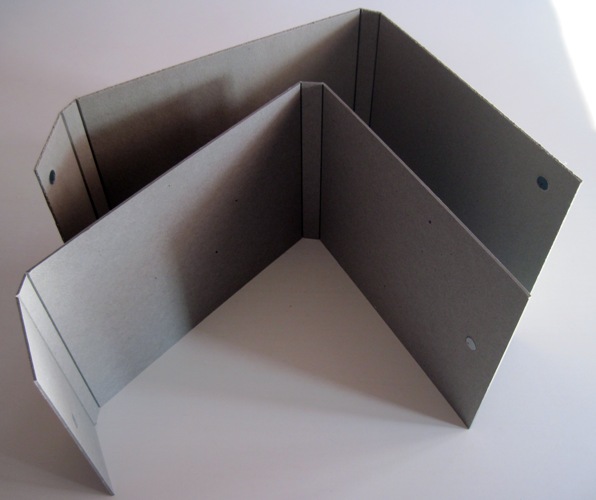

Machines for collapsible boxes, Semi-automatic machine to apply magnets and/or metal platesMAG 1

SEMI-AUTOMATIC MACHINE TO APPLY FROM ONE TO SIX MAGNETS OR METAL PLATES BY USING HOT-MELT GLUE.

Half-automatic machine to groove board cases and to apply magnets (or metal plates) by hot-melt glue

– Board case feeding by hand

– 1 to max 6 magnets per side/1 work cycle.

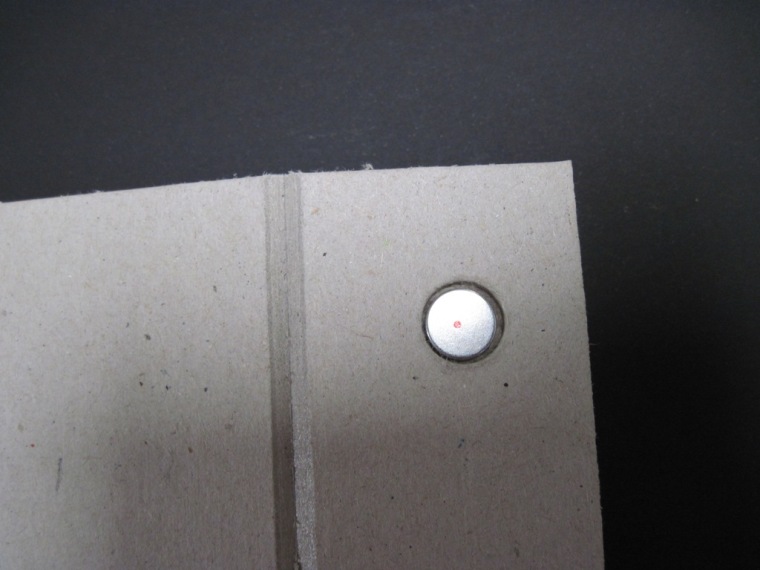

Magnet seat milling, glue application, magnet feeding from charger by fully automatic cycle.

Technical features

Used materials:

– grey board with thickness 1,5 mm up to 4 mm

– magnets with diam. min. 9,5 mm – max 15 mm/thickness 1/1,5/2 mm

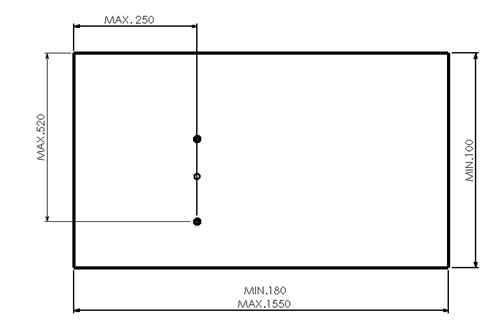

Board width: min. 180 mm – max 1550 mm

Production capacity:

– 14 cycles (with 1 magnet)/minute

– 8 cycles (with 2 magnets)/minute

Power required: 5 Kw

Pneumatic consumption: 150 NL/minute (6 bar)

Overall dimensions: L=2500mm; W=2500mm; H=2100mm;