PP-BOX LINE

Category

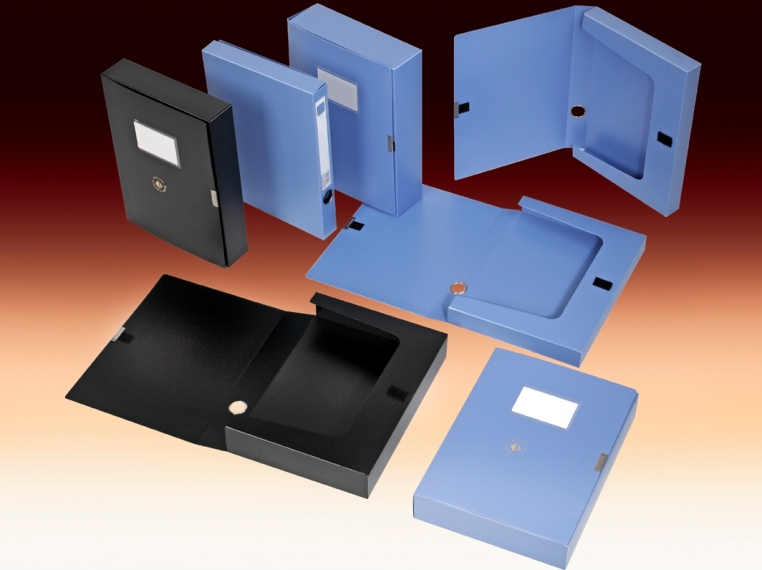

Lines for elastic folders and small cases with snap fasteners

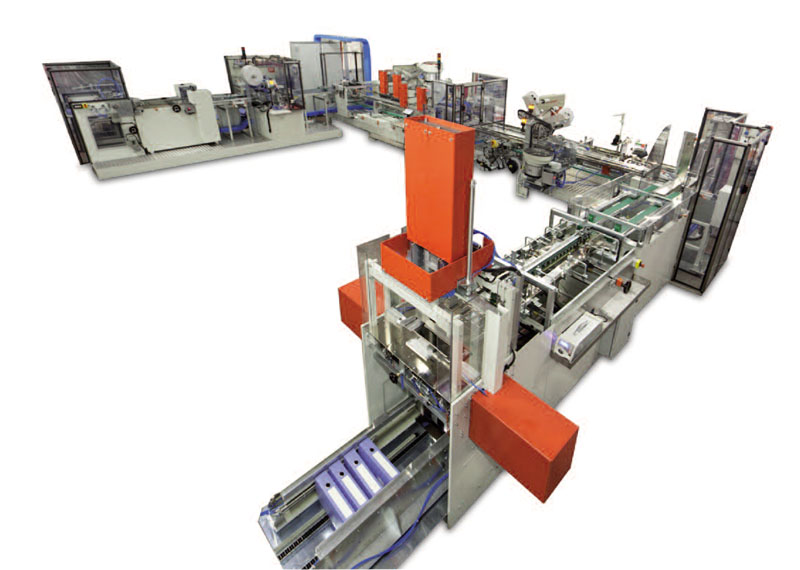

PP-BOX LINE

LINES FOR ELASTIC FOLDERS AND SMALL CASES WITH SNAP FASTENERS

Automatic line for assembling document holding boxes in polypropylene, equipped with hot creaser, pocket welding and paper label positioning units on box spine and front, application of 1 finger eyelet, fastening of one piece of selfadhesive velcro and one metal clip, box folding and shaping devices by ultrasounds.

Technical features

Used materials: polypropylene in sheets with thickness 0,8 up to 1 mm

Box size range: according to the sizes requested by customers

Production capacity: up to 15 pieces/minute

Electrical power: 15 kW

Pneumatic consumption: 950 Nl/min.

Line overall dimensions: depending on the required machine configuration