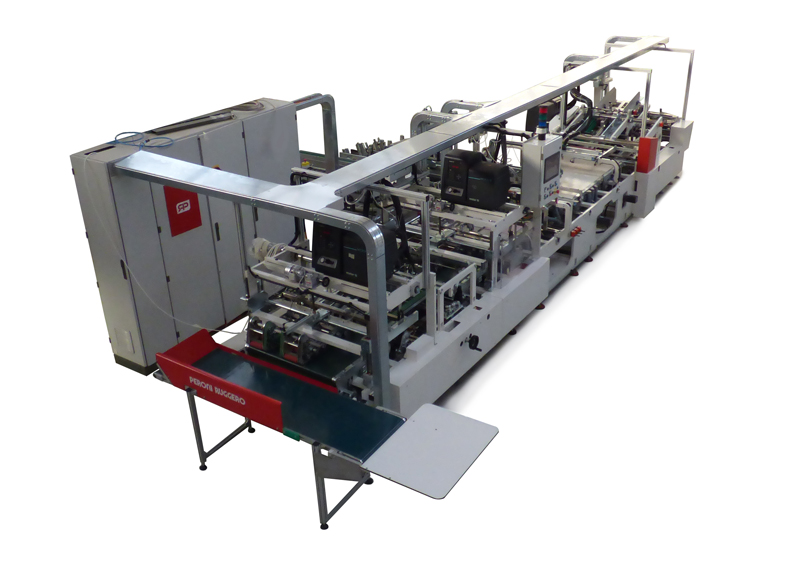

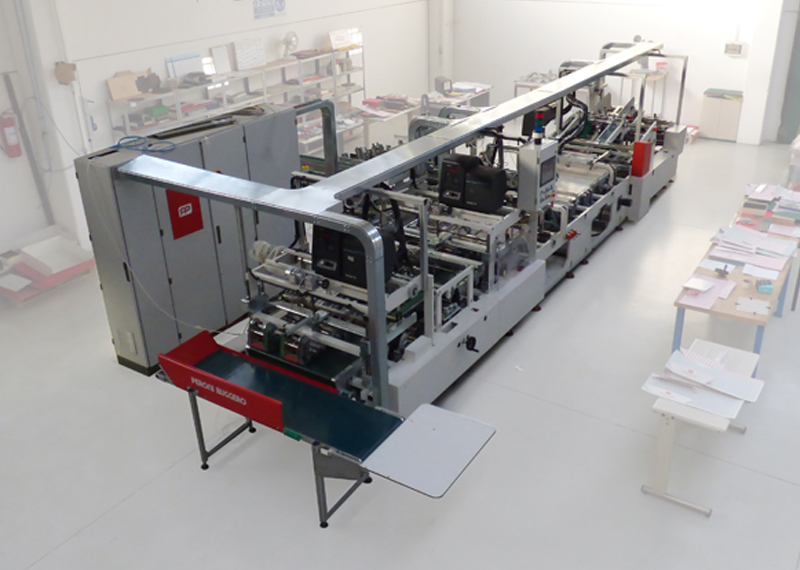

JOLLY BOX 40

Category

Machines for collapsible boxes

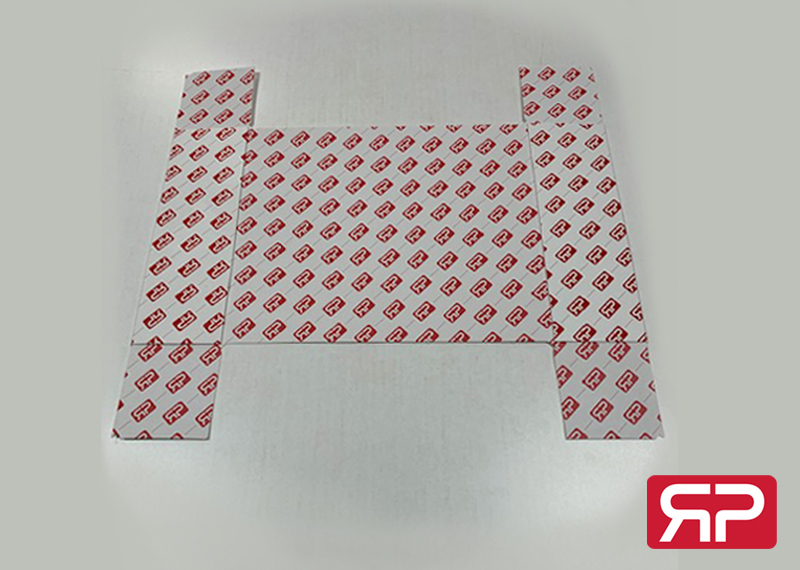

Video presentation for the assembly of collapsible boxes with side wings.

Video presentation for the assembly of book boxes (place rigid box on cover)

JOLLY BOX 40

AUTOMATIC LINE TO ASSEMBLE COLLAPSIBLE BOXES AND BOOK BOXES

Automatic line to assemble rigid boxes and collapsible boxes in 1 or 2 parts – Ideal to manufacture paper-coated luxury packages (even supplied with magnetic closure) as cases and gift boxes for wine, jewels, liqueurs, perfumes – High-capacity equipment running 40 cycles/minute (mechanical speed).

Technical features

Materials to process:

– box board flats already paper-coated (grooved and with magnets)

– with thickness min 1.2 mm up to max 2 mm

Coated flat size range:

min. 400 mm x 220 mm

max 840 mm x 520 mm

– Rigid tray measuring min. 140 mm x 220 mm – max 360 mm x 520 mm

Height min 40 mm – max 100 mm

– Collapsible tray already paper-coated in 1 or 2 parts

measuring min 400 mm x 220 mm – max 840 mm x 520 mm

Ready box size range:

for box cover min 140 mm x 200 mm – max 360 mm x 520 mm

Height 40 mm up to 100 mm

for collapsible boxes in one part min 120 mm x 140 mm max 360 mm x 440 mm

Height 40 mm up to 130 mm

for collapsible boxes in two parts min 140 mm x 220 mm max 360 mm x 520 mm

Height 40 mm up to 130 mm

Gluing: by hot-melt employing Nr 3 glue tanks and Nr. 14 glue guns

Production capacity: up to max 35 cycles/minute for all kinds of boxes

Electrical power required: 20 Kw (glue heaters not considered)

Compressed air required: 300 Nl/minute

Overall dimensions: 7000 mm x 1700 mm x 2100 mm